参加する TMAX, 代理人になる!

参加する TMAX, 代理人になる!

Sales Manager:David

Email:David@tmaxcn.com

Wechat:18659217588

商品番号:

TMAX-RXG700L支払い:

L/C, T/T, Western Union, Credit Cards, Paypal製品の産地:

China出荷港:

Xiamen Portリードタイム:

5 Days証明書 :

CE, IOS, ROHS, SGS, UL Certificate保証 :

Two years limited warranty with lifetime technical support

â .測定原理と応用特性

測定方法は光線透過吸収測定であり、測定される直接物理量は面密度(グラム重量)である。 X 線が材料を透過すると、光線は材料によって反射、散乱、または吸収され、その結果、線強度がいくらか減衰します。減衰は、透過した材料の表面密度に正の相関があります。[30]。

材料のかさ密度が一定または一定である場合、材料の厚さは体積密度換算 (面密度 = 密度 * 厚さ) によって測定できます。

X 線厚さ計は低エネルギー放射線装置であり、電源によって放射線のオンとオフを切り替えることができます。一般に、特別な保護は必要ありません。

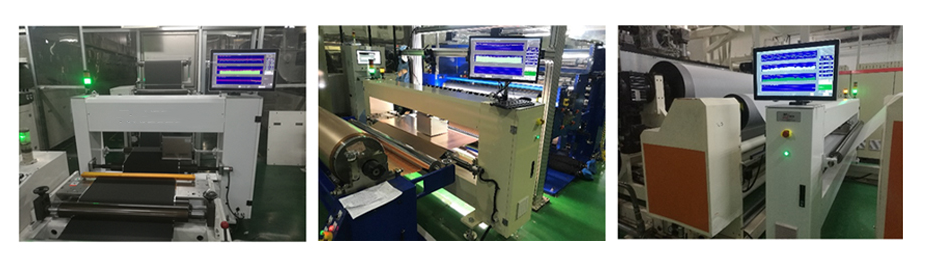

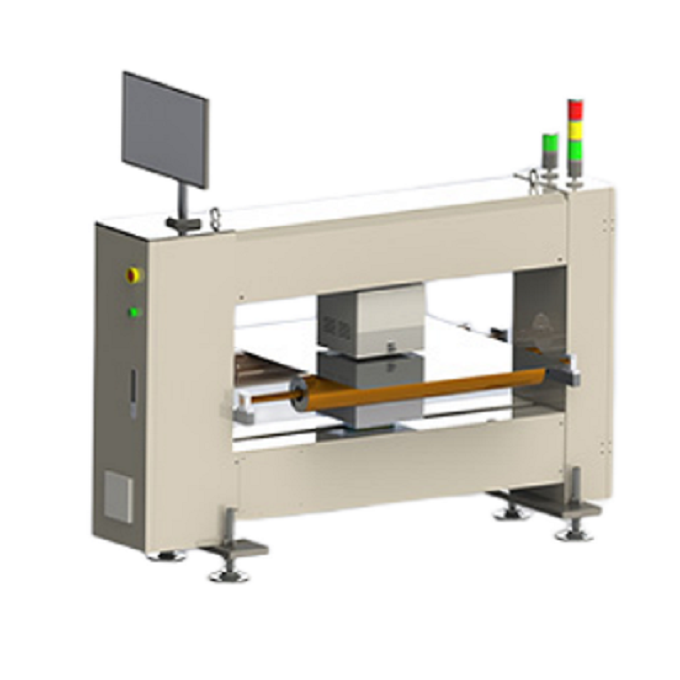

X線厚さ計は一般にO型走査フレームを採用しています。

X線厚さ計はレーザー変位センサーと結合し、C型大理石走査フレームを使用してX線レーザー厚さ測定機を導き出し、面密度と厚さの同時測定を実現し、リチウムコーティングの表面密度とヘッドおよびテールの薄化の測定に使用されます。

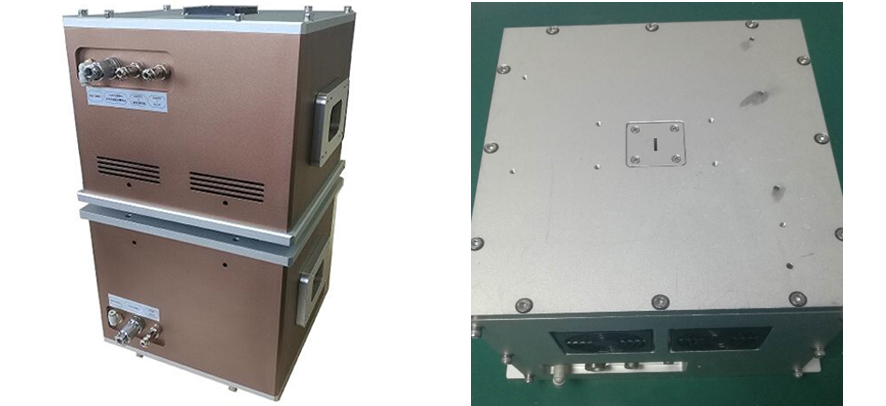

→.優れた性能を誇るX線測定センサー

1)X線測定センサーは、20年の経験を持つ核探知専門家によって構築された装置の重要なコア技術であり、中国ではほとんど見られない高い再現性と長期安定性を備えています。 73

2)X 線送信機は二重閉ループ回路制御システムを採用し、放射線強度の長期安定性と測定の高い再現性を確保します。

3)X 線検出器は、高い信号対雑音比を備えたドイツのプリアンプ回路技術から輸入されたものです。[85]

4)X線送信機は特殊なスリット線コリメーションチャネルと小さなスポット設計を採用し、高信号対雑音比検出器とソフトウェアアルゴリズムを組み合わせて、より高い空間分解能精度と縞欠陥認識を提供します。 .

実際の測定ニーズに従って、X 線送信機の出力スポットは 5 * 5mm Î| 9mm および 2 * 12mm になるように設計されています。

その中で、2 * 12mm レイスポットは、リチウムコーティングエッジの薄化領域のサイズ測定を実現できる独自の利点技術です。

â¢.X 線表面濃度計/厚さ計の技術的特徴と強力な機能モジュール

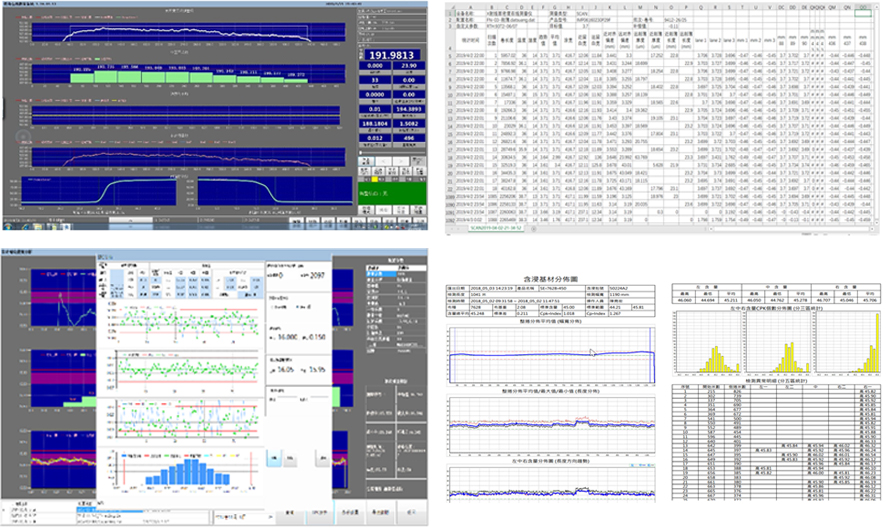

1) スキャニング測定、定点測定、サイクリック定点測定、およびスキャニングと固定点モードの任意の切り替えを実現できます。

2) 単一/複数の等高線、区画線、傾向線、その他の豊富な測定曲線がリアルタイムで表示され、複数の品質データが表示されます。

3) データベースに基づく膨大な合計値データを Excel 形式で保存し、履歴データをクエリして追跡し、履歴曲線を再表示します。

4) 専門的な SPC 統計分析、品質ボリュームレポートを自動的に生成し、顧客のニーズに応じてカスタマイズできます。

5) 複数のプロセス制御ソリューション、リアルタイムのプロセス監視、5 ラインの品質管理、複数の早期警告とアラーム、および超過制限マーキング。

6) 閉ループ自動制御をサポートし、顧客の MES システムとドッキングでき、マルチラックのポイントツーポイント追跡測定を実現できます。

7) 高速測定応答を保証するためのデータ収集カードと制御ボードカード、リアルタイム通信システム、CANOPEN バス通信伝送の独自の研究開発。

8) 優れた使いやすさとフレンドリーなヒューマン・コンピュータ・インターフェース、ワンボタンのインテリジェントな操作。

~.Pパフォーマンスパラメータ

|

アイテム |

X線表面濃度計・膜厚計 |

X線・レーザー一体型装置 |

|

モデル |

RXG700LãRXG750LãRXG850L etc |

RXLG700LãRXLG750L RXLG850L etc |

|

検査項目 |

面密度 |

面密度と厚さ |

|

スキャンフレーム |

Oスキャンフレーム |

C-スキャンフレーム |

|

測定方法 |

スキャニング測定、定点測定、サイクリック定点測定 |

スキャニング測定、定点測定、サイクリック定点測定 |

|

測定範囲 |

0 ~ 1000 g/m² または 0 ~ 1000μm |

0 ~ 1000 g/m² または 0~1000μm |

|

スポットサイズ |

Î|9mmã5*5mm または 2*12mm |

μ9mm(レイ) & 30*1200μm(レーザー) |

|

サンプリング距離 |

1mm |

1mm |

|

繰り返し精度 |

±0.05g/ã¡ または ±0.05% |

±0.05g/ã¡(光線) & ±0.4μm(レーザー) |

→.塗布領域

リチウム電池正極コーティング、リチウム電池隔膜およびコーティング、プラスチックフィルム、不織布、金属箔、ゴムなどのさまざまなシート、コイル、またはコーティングの表面密度(厚さ)の一貫性をオンラインで測定および制御します。

1 標準輸出パッケージ: 内部衝突防止保護、外部輸出木箱パッケージ。

2 最適な方法を見つけるために顧客の要件に応じて速達、航空、海で発送します。

3 配送中の破損については責任を負い、破損部分を無料で交換させていただきます。

© 著作権: 2026 Xiamen Tmax Battery Equipments Limited 無断転載を禁じます.

IPv6 サポートされているネットワーク