参加する TMAX, 代理人になる!

参加する TMAX, 代理人になる!

Sales Manager:David

Email:David@tmaxcn.com

Wechat:18659217588

商品番号:

TMAX-YK-FXC-300支払い:

L/C, T/T, Western Union, Credit Cards, Paypal製品の産地:

China出荷港:

Xiamen Portリードタイム:

5 Days証明書 :

CE, IOS, ROHS, SGS, UL Certificate保証 :

Two years limited warranty with lifetime technical support

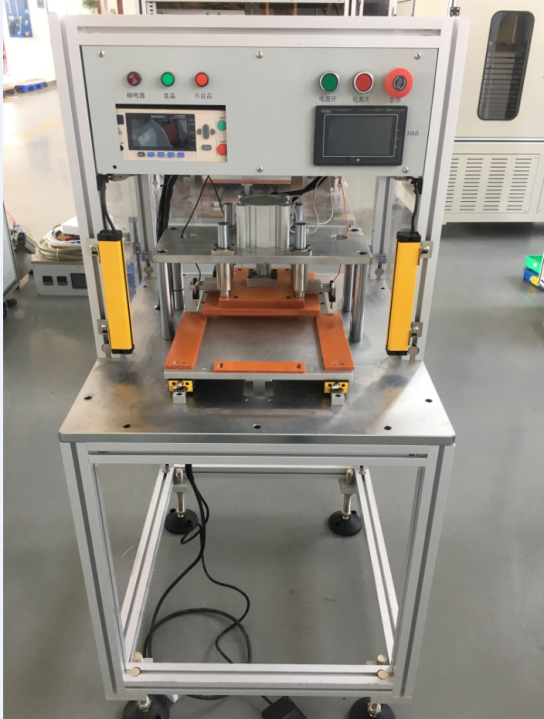

1ã 機材紹介

1.装置応用

この装置は、角形電池の内部抵抗と電圧をテストするように設計されています。PLCが自動的に選別グレードを判断した後、手動選別を実行し、コードをスキャンして容量を読み取ります。側面電圧をテストします。電気コアの厚さをテストします。そしてすべてのデータをMESシステムに接続します。フィクスチャは手動でモバイルフィクスチャに配置され、バッテリーを配置した後、両面制御ボタンを両手でクリックすると、フィクスチャは自動的にプリロード位置に移動して検査プロセスが完了します。最後に、手動で採取し、手動で往復サイクルで操作します。連続生産が実現できます(テスト機能には、コードのスキャンと読み取り能力、電圧と内部抵抗のテストとQRコードへの記録、NGを区別するためのエッジ電圧のテストが含まれます) ; 二次テスト OCV と細胞厚測定および対応するバーコードへのアップロードのためのソフトウェア; すべてのデータが MES システムにアップロードされます。

2.設備構成

手動操作プラットフォーム/電圧試験機構/内部抵抗試験機構/コードスキャン試験機構/側電圧試験機構/主制御機構およびその他の装置で構成されています。

3.装備動作プロセス

バッテリーを給電テストベンチに手動で置き、プラットフォームを介してテストステーションに自動的に入り、電圧、内部抵抗、コードスキャンをテストします。厚み測定機構は押し下げて厚みを測定します。検出後、PLCはあらかじめ設定された選別条件に従って選別し、表示灯が点灯します。エッジ電圧テスト針が連動してアルミニウムフィルムに穴を開け、正極と負極の耳をテストします。最後に、テストデータに従ってバッテリーを手動で分類します。

4.ソフトウェア機能

1) 言語: 簡体字中国語;

2)QRコードの読み取り能力をスキャンします。バッテリーによってデータベースに保存されている電圧/内部抵抗を正確に読み取ります。

プロセス編集および管理機能:

3) プロセス編集および管理機能:

a. 3 つのパラメータのギア検出を設定でき、設定したギアに応じて異なる値を選択できます。

b.テストされたデータ ファイルはコンピュータに保存でき、RS232C インターフェイスを装備してリモート コントロールやデータの取得と分析を行うことができます。

2ã設備概要図(参考)

2ã設備概要図(参考)

3ã装置の技術パラメータ

1. 生産効率ï= 2ppmï=

2. 境界寸法範囲バッテリー:L 80ï½300mmï¼W 50ï½200mm;T 2ï½18mmï¼ Itユーザーが提供するバッテリーのサイズに応じて設計できます。

3. テストモビリティâ¥95%ã装置は8時間動作し、試運転およびメンテナンス時間は1%未満ï=

4. 製品認定率 99%, 製品認定要件は上記の要件に従っています。

4ã機器の技術パラメータ

1. 絶縁抵抗測定範囲ï=100kï½10TΩï=

2. 絶縁抵抗の基本精度:<1G: 1%ï=�1G:3%��10G:5%� 281â¥1T: 10%ï¼

3. 任意の負の電圧を出力ï=1.0VDCï½1000VDCï=<100Vï=電圧ステップ 0.1V--�100V--

4. 電圧ステップ1Vï=基本確度ï=1%ï=

5. 厚さ測定精度:サーボモーターカウンターウェイトテスト、精度±0.1mm

5ã装置の主要コンポーネント

1. シリンダーï=SMC/AirTAC ̄

2. ソレノイドバルブï=SMC/AirTAC ̄

3. 温調計:オムロン・

4. ガイドï=HIWIN/KKTï=

5. リニアベアリングï=ミスミï=

6. PLC:三菱 / パナソニックï¼

7. 誘導スイッチ: オムロンまたはキアンï=

8. タッチスクリーン: 表示と制御ï¼

9. サーボ: パナソニック

6ã設置環境要件

1. 電源の設定ï=AC220Vï=50Hz、電圧変動範囲ï=+10% ï½-10%ï¼

1 標準輸出パッケージ: 内部衝突防止保護、外部輸出木箱パッケージ。

2 最適な方法を見つけるために顧客の要件に応じて速達、航空、海で発送します。

3 配送中の破損については責任を負い、破損部分を無料で交換させていただきます。

© 著作権: 2026 Xiamen Tmax Battery Equipments Limited 無断転載を禁じます.

IPv6 サポートされているネットワーク