参加する TMAX, 代理人になる!

参加する TMAX, 代理人になる!

Sales Manager: Gia

Email: Gia@tmaxlaboratory.com

Wechat: Dingqiuna

商品番号:

TMAX-SK2-12-14TPT3支払い:

L/C, T/T, Western Union, Credit Cards, Paypal出荷港:

Xiamen Portリードタイム:

5 Days証明書 :

CE, IOS, ROHS, SGS, UL Certificate保証 :

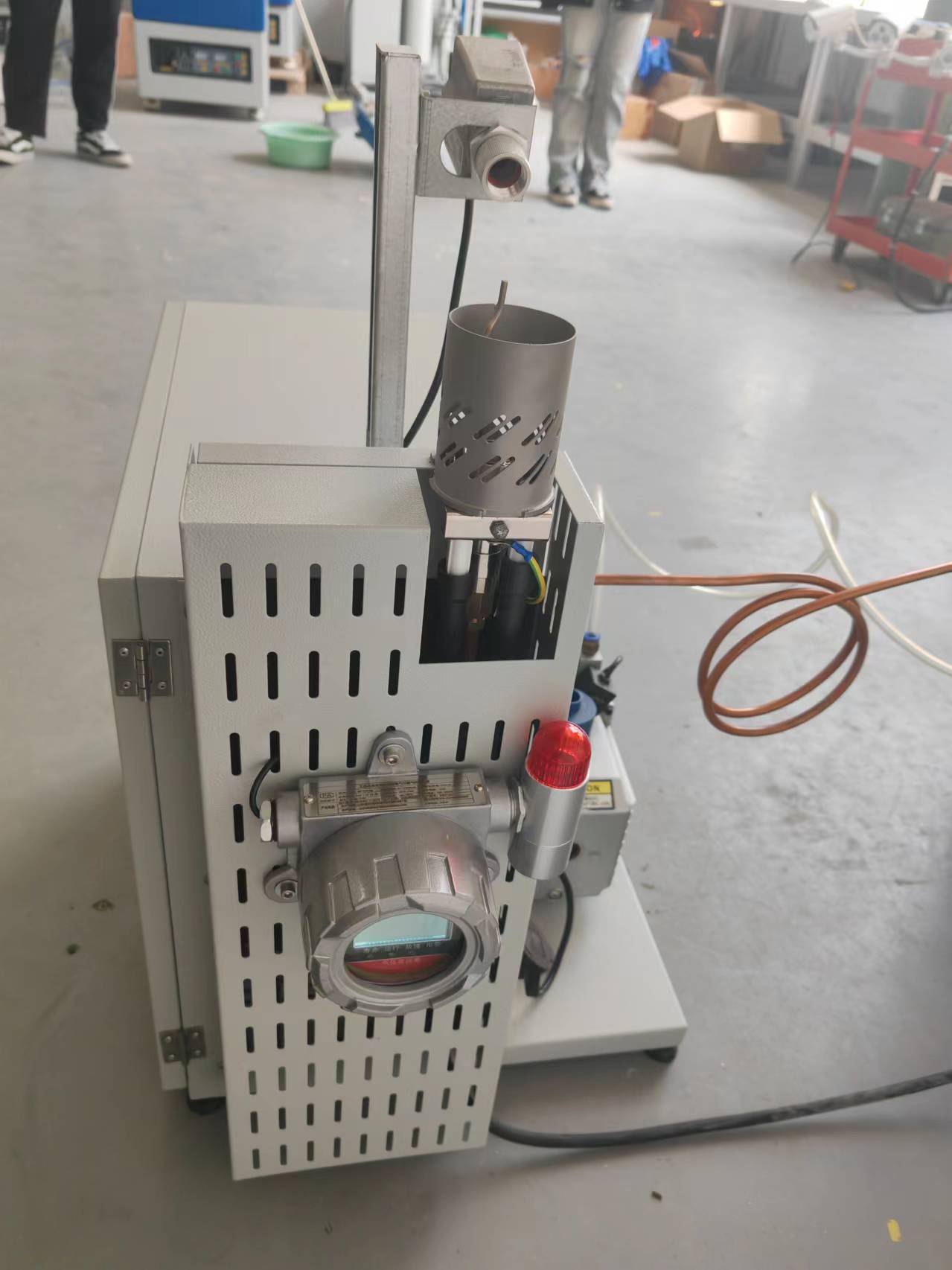

Two years limited warranty with lifetime technical supportアルミナ管と水素安全装置を備えた高温 3 ゾーン 1400C 管状炉

|

メインパラメータパラメータ |

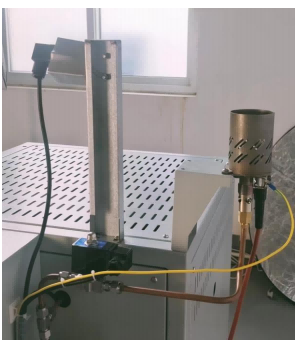

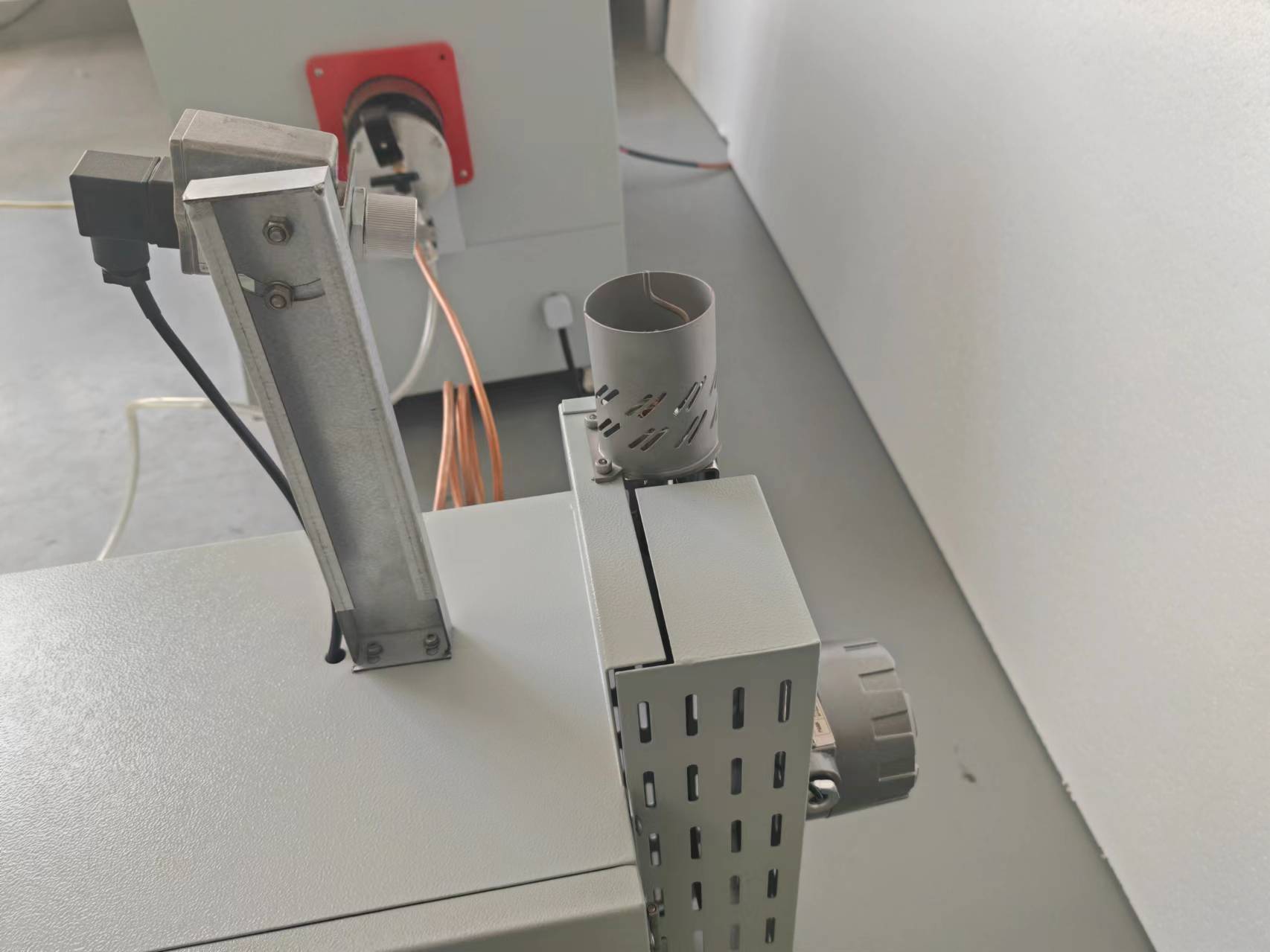

PN: SK2-12-14TPT3 最高温度: 1400℃ 使用温度:0-1300C チューブ径:80mm チューブ加熱ゾーンの長さ:200+200+200mm チューブ材質:アルミナチューブ 加熱速度:0~10 度/分 最高真空度:-0.1Mpa H加熱素子:Mosi2 加熱素子 熱電対:Bタイプ 温度精度:±1° コンピュータ制御ソフトウェア付き |

||

水素 保護システム |

水素点火装置、水素検出装置、水素防爆装置 |

||

|

入口ガス/雰囲気 |

さまざまな保護ガスまたは破壊ガス、不活性ガス、混合ガス、窒素、酸素などを充填できます。 |

||

|

ガスコントロール |

吸気口は 1 つ以上設置でき、各吸気口にはニードルバルブが設けられ、真空計が接続されています。エア出口は1ヶ所に接続されており、全穴にニードルバルブが付いています。真空ポンプを装備しています。 |

||

|

外観デザイン |

電気炉は人間化されたデザインを採用し、美しくて操作が簡単で、塗料の外層は高温ベーキング技術でスプレーされます。 高温耐性、耐酸化性、耐酸性、耐アルカリ性。 色は経年変化に強い色調を選択し、長期間の使用による外観の色褪せを引き起こしません。 |

||

|

炉室材質 |

世界最先端の軽量アルミナセラミックファイバーを採用し、優れた断熱効果、軽量、耐高温性、耐寒性、耐熱性を備え、亀裂、結晶化、スラグがなく、焼成物の汚染の心配がありません。製品。省エネ効果は旧電気炉の60~80%です。 |

||

|

炉室の設計 |

炉は階段状のアセンブリ構造を採用し、機械的法則を統合し、均一な力の加熱プロセスで効果的に炉を確保し、熱が分散しにくいことを保証し、炉の耐用年数を延ばします。 |

||

|

炉シェル構造 |

電気炉シェルは二重層強制空冷構造を採用しており、電気炉は最高温度で動作し、シェルの外部温度は室温に近くなり、偶発的な怪我を避けることができます。 |

||

|

シール方法 |

304 ステンレス鋼フランジを採用し、取り付けと取り外しが簡単、耐酸化性、耐酸性および耐アルカリ性、二重シール、確実なシールを実現します。 |

||

|

温度制御 |

国際的な高度な温度コントローラーを採用し、30 個のプログラム可能な PID セルフチューニング、自動温度上昇、自動温度降下、デューティなしを備えています。 コンピュータ制御ソフトウェアを使用。 |

||

|

温度管理セキュリティ |

電気炉は集積回路、モジュール制御、二重回路保護(部分温度保護、超高温保護、カップリング保護、過電流保護、過圧保護およびその他の保護機能)を採用し、電気炉の動作を安定かつ信頼性の高いものにします。安全です。 |

||

|

保証 |

ユーザーが損傷した発熱体、冷却ファン、熱電対、セラミック チューブを除く、生涯サポート付きの 1 年間の限定保証。 注意: 腐食性ガスや酸性ガスの使用によって生じた損傷、および誤った操作や使用によって生じた損傷は、1 年間の限定保証の対象外です。 |

||

|

注目 |

コランダムチューブは急冷や急加熱には耐性がありません。使用前に予熱する必要があり、両端にセラミックブロックを配置する必要があります。加熱および冷却プロセス中、速度が速すぎたり、空気流量が大きすぎたりすることはできません。 150ml/minを推奨します。不均一な加熱や破損を避けてください |

||

|

証明書: CE、ISO&UL |

|

||

|

標準パッケージ付属品: |

|||

|

電気炉 |

1セット |

|

|

|

高温用手袋 |

1ペア |

|

|

|

クルーシブルフック |

1個 |

|

|

|

石英管 |

1個 |

|

|

|

ステンレス鋼フランジ |

1セット |

|

|

|

予備の発熱体 |

2個 |

|

|

|

チューブストッパー |

2個 |

|

|

|

10mmエアパイプ |

|

|

|

|

ユーザーマニュアル |

1冊 |

|

|

|

真空ポンプ |

1セット |

|

|

あなたの住所を詳しく教えてください。そうすれば、私たちはあなたに運賃を送ることができます。

1 標準輸出パッケージ: 内部衝突防止保護、外部輸出木箱パッケージ。

2 最適な方法を見つけるために顧客の要件に応じて速達、航空、海で発送します。

3 配送中の破損については責任を負い、破損部分を無料で交換させていただきます。

© 著作権: 2026 Xiamen Tmax Battery Equipments Limited 無断転載を禁じます.

IPv6 サポートされているネットワーク