Perovskite Solar Cell Lab Plant: Revolutionizing Solar Energy Research and Manufacturing

Perovskite solar cells (PSCs) are among the most promising innovations in the field of renewable energy. With their potential for high efficiency, low cost, and flexibility in production, perovskite-based solar cells are rapidly gaining attention as a next-generation photovoltaic technology. Setting up perovskite solar cell lab line is essential for both research and commercial production to refine the technology and scale up manufacturing.

In this article, we will discuss what perovskite solar cells are, the key processes involved in a Solar Cell Research Equipment, and how such facilities are critical for advancing this cutting-edge technology.

●What Are Perovskite Solar Cells?

Perovskite solar cells are a type of thin-film solar cell that use a perovskite-structured compound as the light-harvesting active layer. The most commonly used material in PSCs is ahybrid organic-inorganic lead halide perovskite, but research continues on developing alternative materials to improve performance and reduce environmental concerns, particularly related to lead content.

Advantages of Perovskite Solar Cells:

1.High Efficiency: Perovskite solar cells have shown rapid improvements in power conversion efficiency (PCE), with lab-scale cells achieving over 25% efficiency in recent years.

2.Low Production Cost: PSCs can be manufactured using relatively inexpensive materials and processes, making them a cost-effective alternative to traditional silicon-based solar cells.

3.Versatility: Perovskite materials can be deposited on flexible substrates, allowing for the creation of lightweight and flexible solar panels.

4.Tunable Bandgap: The bandgap of perovskite materials can be adjusted by changing their composition, making them suitable for tandem solar cells and other specialized applications.

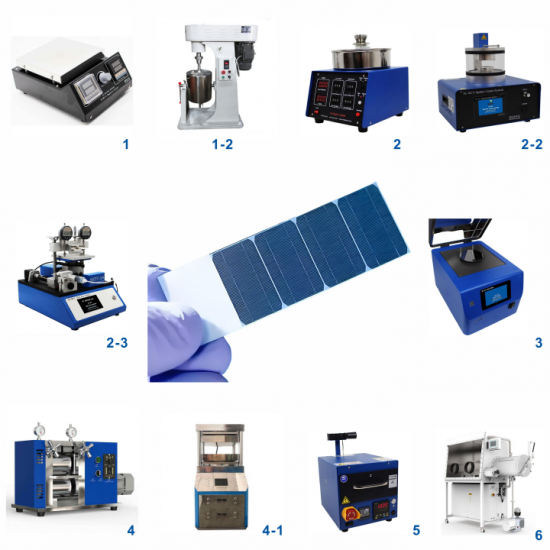

●Key Components of a Perovskite Solar Cell Lab Plant

Aperovskite solar cell lab plant focuses on the research, development, and small-scale production of perovskite solar cells. The setup includes specialized equipment for material synthesis, thin-film deposition, cell assembly, and testing. Here’s a breakdown of the key components and stages involved:

1.Materials Synthesis and Preparation

The process begins with synthesizing and preparing the materials that make up the perovskite layer, including lead-based compounds, organic molecules, and halides. Research labs often experiment with different compositions to improve the stability and efficiency of the solar cells.

-Synthesis Techniques: Materials for perovskite solar cells can be synthesized throughsolution processing,thermal evaporation, orvapor deposition methods.

-Purification: Purification of raw materials is essential to ensure high-quality films with minimal defects, which is crucial for achieving high-efficiency solar cells.

2.Substrate Preparation

The substrates used in perovskite solar cells can vary depending on the desired characteristics. Common substrates includeglass,plastic, andmetal foils, often coated with transparent conducting oxides (TCOs) such asindium tin oxide (ITO) orfluorine-doped tin oxide (FTO).

Substrate preparation includes:

-Cleaning: Substrates are cleaned to remove contaminants that may interfere with film deposition.

-Coating: In some cases, substrates are coated with additional layers (e.g., hole transport layers) to optimize cell performance.

3.Thin-Film Deposition

The core of perovskite solar cell production is thedeposition of thin films that make up the active layers of the cell. These layers typically include:

-Electron Transport Layer (ETL): Facilitates electron movement from the perovskite layer to the electrode.

-Perovskite Absorber Layer: The light-absorbing layer that converts sunlight into electrical energy.

-Hole Transport Layer (HTL): Enhances the extraction of positive charges (holes) and transports them to the electrode.

Film deposition techniques include:

-Spin Coating: A widely used technique in lab-scale production where a solution is dropped onto the substrate and spun at high speeds to form a uniform thin film.

-Doctor Blade Coating: A scalable deposition technique suitable for larger substrates.

-Vacuum Deposition: A method that involves evaporating materials in a vacuum chamber and depositing them as thin films on the substrate.

-Slot-Die Coating: Used for continuous deposition in roll-to-roll manufacturing.

Each of these techniques has its advantages depending on the scale and goals of the lab plant.

4.Annealing and Crystallization

After the perovskite layer is deposited, it undergoesannealing, a heating process that improves the crystallization of the material. Proper crystallization is essential for achieving high efficiency and stability in perovskite solar cells.

-Temperature Control: The annealing temperature and duration need to be carefully controlled to avoid damaging the film while ensuring optimal crystal formation.

5.Electrode Deposition

The next step is depositing thetop electrode, which is typically made ofgold,silver, or other conductive materials. This step completes the solar cell by providing the electrical contacts needed to collect and transmit the electricity generated by the perovskite layer.

-Vacuum Sputtering andThermal Evaporation are commonly used methods for depositing metal electrodes in lab settings.

6.Encapsulation

Perovskite solar cells are sensitive tomoisture andoxygen, which can rapidly degrade their performance. Therefore, encapsulation is a crucial step to protect the cells from environmental exposure.

-Encapsulation Materials: Glass, transparent polymers, and barrier films are used to encapsulate the cells and prevent degradation.

-Techniques: Techniques such aslamination orsealing are employed to provide airtight encapsulation for long-term stability.

7.Testing and Characterization

Once the solar cells are fabricated, they undergo rigorous testing and characterization to assess their performance and durability. This includes:

-Power Conversion Efficiency (PCE) Measurement: Determines how efficiently the cell converts sunlight into electricity.

-Stability Testing: Evaluates how well the cell performs under conditions of heat, humidity, and prolonged light exposure.

-Spectral Response: Analyzes the cell’s ability to absorb different wavelengths of light, which is important for optimizing the bandgap of the perovskite material.

-Thermal Testing: Assesses how temperature variations affect cell performance and longevity.

●Automation and Scaling in a Perovskite Solar Cell Lab Plant

While lab plants primarily focus on research and development, automating certain aspects of the process can increase throughput and enable small-scale production. Automated deposition systems, annealing ovens, and testing equipment can help researchers optimize processes and pave the way for future industrial-scale manufacturing.

Scale-up Challenges:

-Reproducibility: Achieving consistent, high-quality results when scaling from lab-scale to mass production remains a key challenge for perovskite solar cells.

-Long-term Stability: Addressing the degradation issues associated with environmental exposure is critical for large-scale adoption.

-Lead-Free Alternatives: Developing lead-free perovskite materials is an ongoing area of research to mitigate environmental concerns and comply with regulations.

●Conclusion

Theperovskite solar cell lab plant plays an essential role in pushing the boundaries of solar energy technology. By offering the infrastructure for research, material development, and small-scale production, these facilities contribute to the rapid advancements in perovskite solar cell efficiency and stability.

Through the optimization of thin-film deposition techniques, substrate preparation, and advanced testing methods, lab plants are helping to refine the processes necessary for scaling up perovskite solar cell production for widespread commercial use. As the technology matures, these lab plants will be critical in bridging the gap between research and large-scale manufacturing, ultimately contributing to a more sustainable future powered by clean, efficient solar energy.