The Future of Solar Energy: Inside the Perovskite Solar Cell Assembly Line

Perovskite solar cells (PSCs) are rapidly emerging as one of the most promising technologies in the renewable energy sector. With their high efficiency, low production costs, and potential for versatile applications, PSCs are poised to revolutionize the solar energy industry. To capitalize on this potential, manufacturers are developing specialized assembly lines for the mass production of perovskite solar cells. In this blog post, we will explore the key components of a perovskite solar cell assembly line, how it works, and why it represents a significant leap forward in solar technology.

● What Are Perovskite Solar Cells?

Perovskite solar cells are a type of photovoltaic cell that uses perovskite-structured compounds as the light-harvesting active layer. These materials have garnered attention due to their high absorption efficiency, tunable bandgap, and ease of fabrication. Unlike traditional silicon-based solar cells, perovskite cells can be produced using low-cost, solution-based processes, which significantly reduce manufacturing costs.

In recent years, the efficiency of perovskite solar cells has soared, reaching levels comparable to or even surpassing traditional silicon solar cells. This, combined with the potential for lightweight, flexible, and semi-transparent designs, makes perovskite solar cells an exciting prospect for a wide range of applications, from residential solar panels to wearable electronics and building-integrated photovoltaics (BIPV).

● The Importance of a Dedicated Assembly Line

The production of perovskite solar cells requires a controlled and precise manufacturing process to achieve high efficiency and durability. A dedicated assembly line for perovskite solar cells ensures that each cell is produced with the consistency, quality, and scalability needed for commercial applications. Here’s why a specialized assembly line is essential:

1.Precision: The fabrication of perovskite solar cells involves delicate processes like thin-film deposition, layering of materials, and encapsulation. A dedicated assembly line is designed to handle these processes with high precision, ensuring that each cell meets strict performance criteria.

2.Scalability: The scalability of perovskite solar cell production is crucial for meeting global energy demands. An assembly line optimized for perovskite technology enables manufacturers to scale up production efficiently, making the technology more accessible and affordable.

3.Quality Control: To ensure the long-term stability and performance of perovskite solar cells, stringent quality control measures are necessary. A dedicated assembly line incorporates advanced testing and monitoring systems at each stage of production, ensuring that only high-quality cells reach the market.

4.Cost Efficiency: By streamlining the production process and reducing material waste, a specialized assembly line helps lower the overall cost of perovskite solar cells, making renewable energy more competitive with traditional energy sources.

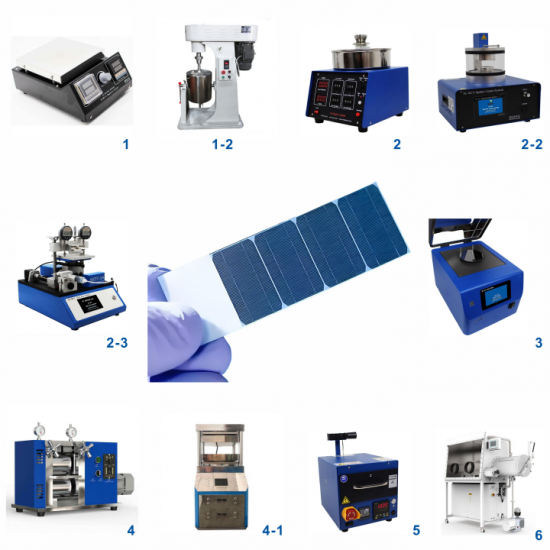

● Key Components of the Perovskite Solar Cell Assembly Line

A perovskite solar cell assembly line typically includes several key components and stages:

1.Substrate Preparation: The first step in the assembly line is preparing the substrate, which serves as the foundation for the solar cell. Common substrates include glass, plastic, or metal foils, depending on the intended application. The substrate is cleaned and treated to ensure a smooth surface for the subsequent layers.

2.Perovskite Layer Deposition: The heart of the perovskite solar cell is the perovskite layer itself. This layer is deposited onto the substrate using techniques such as spin-coating, slot-die coating, or vapor deposition. The choice of deposition method depends on the desired film quality and the scale of production. This step requires precise control over temperature, humidity, and deposition rate to achieve uniform and high-quality films.

3.Electron and Hole Transport Layers: To facilitate the movement of electrons and holes generated by light absorption, electron transport layers (ETL) and hole transport layers (HTL) are applied on either side of the perovskite layer. These layers are typically thin films of materials like titanium dioxide (TiO2) or spiro-OMeTAD, and they play a crucial role in the overall efficiency of the solar cell.

4.Electrode Application: The next step involves applying electrodes to the solar cell. Transparent conductive oxides (TCOs) like indium tin oxide (ITO) are commonly used as the front electrode, while metals like silver or gold are used for the back electrode. These electrodes collect and transport the electrical current generated by the solar cell.

5.Encapsulation: To protect the perovskite solar cell from environmental factors such as moisture and oxygen, which can degrade its performance, the cell is encapsulated using protective coatings or laminates. This step is critical for ensuring the long-term stability and durability of the solar cell.

6.Testing and Quality Assurance: After assembly, each perovskite solar cell undergoes rigorous testing to assess its efficiency, stability, and overall performance. This includes measurements of power conversion efficiency (PCE), open-circuit voltage, short-circuit current, and fill factor. Cells that meet the required specifications are then prepared for integration into solar panels or other applications.

● Advances in Perovskite Solar Cell Assembly Technology

The technology behind perovskite solar cell assembly is continuously evolving, with several key advancements driving improvements in efficiency, scalability, and cost-effectiveness:

1.Roll-to-Roll Processing: Roll-to-roll (R2R) processing is a manufacturing technique that enables the continuous production of perovskite solar cells on flexible substrates. This method significantly reduces production costs and is ideal for large-scale manufacturing. R2R processing is expected to be a game-changer for the commercialization of perovskite solar cells.

2.Automation: Automation plays a crucial role in increasing the efficiency and consistency of the assembly line. Automated systems can handle tasks such as material deposition, layer alignment, and quality inspection with greater precision and speed than manual processes.

3.Advanced Materials: Research into new materials for the transport layers and encapsulation is leading to the development of more efficient and stable perovskite solar cells. These materials improve the cell’s performance and extend its lifespan, making perovskite technology more viable for long-term applications.

4.Hybrid Technologies: Combining perovskite solar cells with other technologies, such as tandem cells that stack perovskite and silicon layers, is another area of innovation. These hybrid approaches aim to achieve higher efficiencies by taking advantage of the complementary properties of different materials.

● Conclusion

The perovskite solar cell assembly line represents a significant advancement in the field of renewable energy. By enabling the efficient, scalable, and cost-effective production of high-performance solar cells, these specialized assembly lines are helping to accelerate the adoption of solar energy worldwide. As the technology continues to mature, we can expect perovskite solar cells to play a key role in the global transition to a more sustainable energy future.

Whether used in residential solar panels, commercial installations, or innovative new applications, perovskite solar cells are poised to make a lasting impact—and the assembly lines behind them are at the forefront of this solar revolution.