参加する TMAX, 代理人になる!

参加する TMAX, 代理人になる!

Sales Manager:David

Email:David@tmaxcn.com

Wechat:18659217588

商品番号:

TMAX-A-005支払い:

L/C, T/T, Western Union, Credit Cards, Paypal製品の産地:

China出荷港:

Xiamen Portリードタイム:

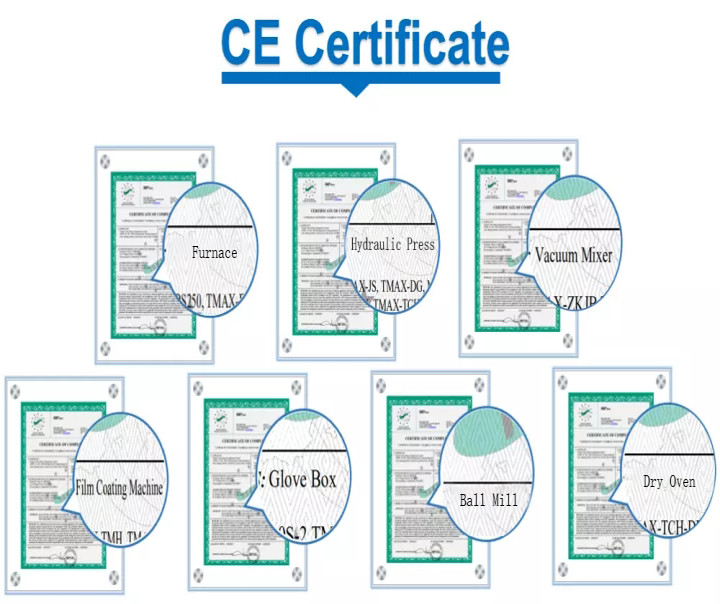

5 Days証明書 :

CE, IOS, ROHS, SGS, UL Certificate保証 :

Two years limited warranty with lifetime technical support

機能

– ラミネート技術ギャップまたは連続コーティングシートのダイカット、スタックプロセスを適用します。

– 圧延による原料、フローティングロール張力制御、供給後の自動補正動作、スライスマニピュレーターによる自動型抜き成形行進により、プレートが自動的に積み上げられ、飼い葉桶に持ち上げられます。全プロセスを備えたキャリアによる補助搬送、およびシングルプットシングルエンド、偏向、テンションキャッシュ、ダスト、およびその他の機能を備えたキャリア。残材はキャリアベルトによって残材収集バレルに輸送されます。

– スリッティングツールエプロン: 斬新な 110 ツールエプロン、Î|110 枚のブレード、繰り返し研磨された上下のブレード

ハイライト

â 回転させることで自動調整し、プラットフォームに接続します

– フローティングローラー張力閉ループ制御材料、および材料関数の保存

â シングルプットシングルクローズ、自動補正および収集付きキャリア

â フローティングロールストリップ張力閉ループ張力制御

â キャリアストリップをブラシを通して塵吸引装置に接続します

– マーチングを使用してストリップを正確に修正します

â 高精度光ファイバー位置決めサーボ精度で長さを確認し、ピンチして送ります

â 一度に複数のピースをダイカットできます

? スタッキングマニピュレーターが自動的にトラフに取り込まれます

â トラフはアノード/カソードの高さに適切に適合します

â 残材が入ったリテイナーは残材バレルに自動的に配送され、収集されます

â トップコーン型ローリングは自動気動車と接続可能(オプション)

– 送り精度を確保するための送りモードの偏りを二重に修正

? キャリアには巻き戻し機能があります (オプション)

â スタッキング トラフ スロット搬送引き紐ドッキングと自動トラフ交換 (オプション)

~ ギャップコーティング、連続コーティングプロセスの受け入れ材料に適応可能

私たちは引き続きプレミアム スロット ダイ コーター を提供します。

技術パラメータï=

|

アイテム |

HBMQ-350J(L) |

HBMQ-450J(L) |

HBMQ-530J(L) |

|

対策 |

3700×1400×1850(長さ×幅×高さ) |

3600×1750×1800(長さ×幅×高さ) |

4200×1600×1900(L×W<192×H) |

|

重量 |

約3.5T |

約4.5T |

約6T |

|

パワー |

AC 380V /50HZ、電力4.5KW |

AC 380V /50HZ、電力 7.0KW |

AC 380V /50HZ、電力8.5KW |

|

空気源 |

0.6Mpa、20L/min |

0.6Mpa、20L/min |

0.6Mpa、20L/min |

|

アクション |

98% |

98% |

98% |

|

最大成形面積 |

長さ*幅:330×260mm |

長さ*幅:430×380mm |

長さ*幅:530×400mm |

|

適用可能なシート範囲 |

長さ:50-260mm、幅:30-320mm |

長さ:60-430mm、幅:50-380mm |

長さ:80-420mm、幅:50-530mm |

|

成形バリ精度 |

→0.03mm |

→0.03mm |

?0.03mm |

|

容量 |

10~35回/分 |

10~35回/分 |

10~35回/分 |

|

材料をワイドに供給 |

?350mm |

~450mm |

~530mm |

|

アクション |

98% |

98% |

98% |

|

切り粉 |

→0.5mm |

?0.5mm |

?0.5mm |

1 標準輸出パッケージ: 内部衝突防止保護、外部輸出木箱パッケージ。

2 最適な方法を見つけるために顧客の要件に応じて速達、航空、海で発送します。

3 配送中の破損については責任を負い、破損部分を無料で交換させていただきます。

© 著作権: 2026 Xiamen Tmax Battery Equipments Limited 無断転載を禁じます.

IPv6 サポートされているネットワーク