参加する TMAX, 代理人になる!

参加する TMAX, 代理人になる!

Sales Manager:David

Email:David@tmaxcn.com

Wechat:18659217588

商品番号:

TMAX-A-022支払い:

L/C, T/T, Western Union, Credit Cards, Paypal出荷港:

Xiamen Portリードタイム:

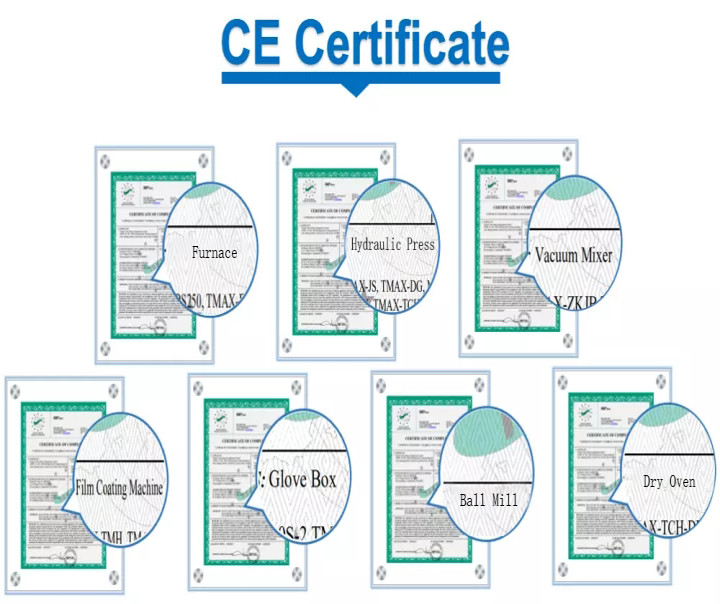

20 Days証明書 :

CE, IOS, ROHS, SGS, UL Certificate保証 :

Two years limited warranty with lifetime technical support

機能

â 高温重合を達成するために、スタンディングでの自動ロードおよびアンロードベーキング治具、ベーキングオーブン、ベーキング炉冷却に適しています。

特長

â 材料を手動でジグにロードし、回転テーブルからマニピュレータークランプをベーキングに段階的に供給します

– 精密位置決め装置および自動校正装置のベーキング器具が施設から撤去される

â サーボ制御によってロックされたベーキングジグ

â 焼成炉と冷却炉はプレートチェーンコンベア、閉ループ制御を使用

– ベーキング治具張力サーボ制御、タッチスクリーン設定内の張力、張力精度 ±0.25%

? 焼成炉温度制御精度 ±3 ? (セキュリティドアから1メートル以内の距離を除く)

â ベーキング後のバッテリー厚さの精度: プラスまたはマイナス 3.0% T (T はバッテリーの平均厚さ)

– 冷却後、温度が 40 未満 – 器具を焼くとき

– ヘッドコンポーネント構造は可動ローラー構造を採用しており、メンテナンスが容易で、分解が容易です

技術パラメータ (参考用)ï=

|

アイテム |

メインパラメータ |

|

対策 |

(長さ*幅*高さ): 9800*3500*2350ミリメートル |

|

重量 |

約10T |

|

パワー |

AC380V/50HZ、72Kw |

|

空気源 |

→0.6Mpa、150L/Min |

|

真空源 |

→-85Kpa、60L/分 |

|

適用範囲 |

長さ:50-180mm、幅:30-130mm、厚さ:2-10mm |

|

容量 |

15-20PPM(焼き時間:4時間、一度に4枚、厚さ〜5mm) |

|

コールドソース |

冷却水、10-18?、吐出水頭:20M |

|

アクション |

â§99% |

1 標準輸出パッケージ: 内部衝突防止保護、外部輸出木箱パッケージ。

2 最適な方法を見つけるために顧客の要件に応じて速達、航空、海で発送します。

3 配送中の破損については責任を負い、破損部分を無料で交換させていただきます。

© 著作権: 2026 Xiamen Tmax Battery Equipments Limited 無断転載を禁じます.

IPv6 サポートされているネットワーク